Filipino farmers engaged in tilapia cultivation now have the opportunity to enhance fish production while markedly minimizing environmental impact, thereby optimizing operational costs. This advancement can be realized through the implementation of the in-pond raceway system (IPRS).

“The IPRS is three times more productive than a pond of the same size without IPRS,” explained Dr. Charles Hall, director of the animal and aquaculture nutrition meal of the U.S. Soybean Export Council (USSEC).

Originally developed in the early 1990s by Auburn University in Alabama, the IPRS has only recently been assessed and adopted for commercial use.

Traditional fish farming methods have revealed various constraints related to natural resources, such as water and energy, in addition to environmental challenges. These limitations hinder the growth of the aquaculture sector. However, the IPRS effectively addresses these issues and concerns.

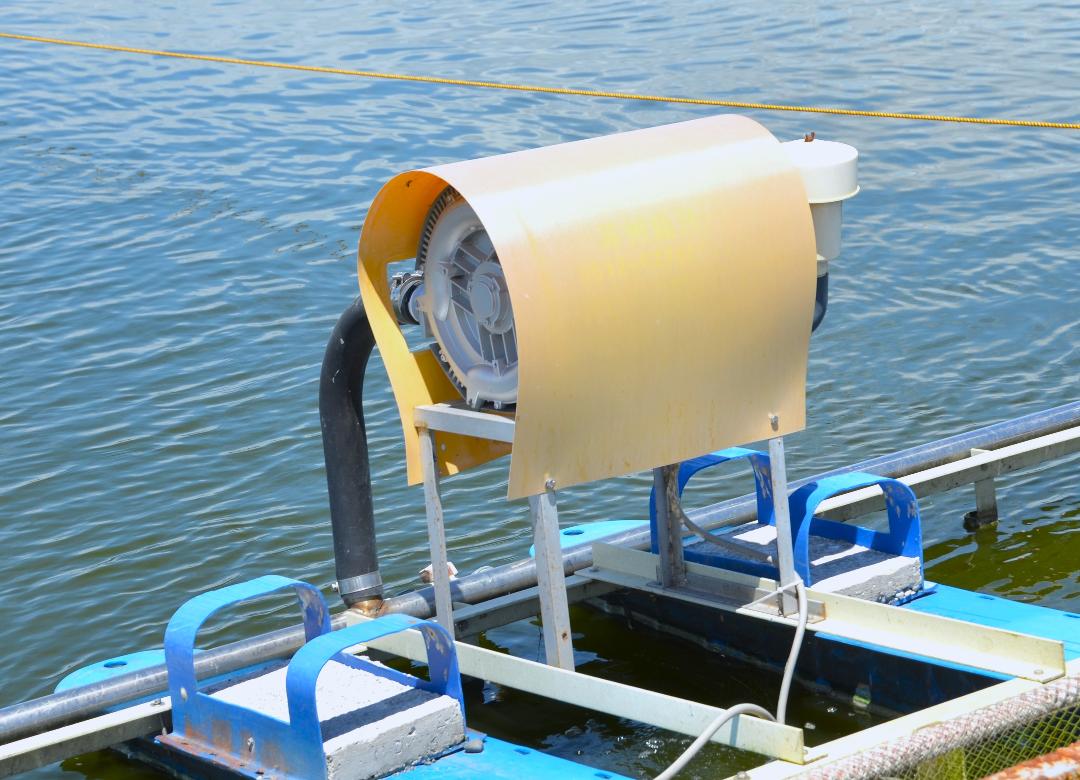

The IPRS concept involves the aggregation of fed fish within designated cells or “raceways” in a pond. These raceways are equipped with a continuous water circulation system to ensure optimal water quality, thereby enhancing feed management and various production metrics.

The technology has the potential to decrease the accumulation of solid waste in the pond by concentrating it and facilitating its removal from the downstream end of the raceway units.

The key components of the IPRS technology include water circulation, mixing, and aeration, which are essential for expediting the assimilation of organic loading in the pond that supports fish feeding.

The USSEC promotes technologies which facilitate effective, efficient, and sustainable aquaculture practices. In the case of IPRS, the fish are able to convert soybean meal into muscle protein more efficiently than other livestock, thereby underscoring the significance of economically viable aquaculture production.

The Alsons Aquaculture Corporation (AAC) is currently utilizing the IPRS in its aquaculture ponds located in Maribulan, Alabel, Sarangani. This marks the inaugural implementation of such a system in the Philippines.

The introduction of IPRS to AAC was facilitated by the USSEC, which emphasizes the importance of distinguishing and enhancing preference while securing market access for soybean utilization in human consumption, aquaculture, and livestock feed across over 80 countries worldwide.

The construction of the pond commenced in 2020 and consists of four cells, each with a volume of approximately 220 cubic meters. These four cells are situated within a two-hectare pond area, which has a water depth of two meters.

After a duration of ten months, the system became operational.

“The IPRS system allows us to maintain higher densities of fish within a recirculating water system,” explains Israel M. Mosquera, the manager of the ACC Grow-out Operations.

“The water is continuously circulated around the pond by a water impeller, which enhances the oxygen levels in the water and generates a current that facilitates circulation throughout the system. This capability enables the system to support fish culture at high densities.”

According to him, phytoplankton and other microorganisms that live in water which perform photosynthesis are crucial for sustaining the ecological balance of the pond.

The AAC is renowned for its bangus production; however, in recent years, it has expanded its operations to include the cultivation of various fish species. Tilapia has emerged as a viable alternative to bangus, prompting the company to commence tilapia farming in 2017.

Currently, tilapia farming accounts for approximately 80% of the company’s 320 hectares of ponds located in Alabel, Sarangani. “Tilapia has become one of the favored fish among Filipinos,” states Jerico S. Pascual, the vice president of the company’s processed foods manufacturing division. “If we encounter challenges in cultivating bangus, we will likely face similar difficulties with tilapia.”

Over the five years that AAC has been engaged in tilapia farming, it has observed that tilapia yields are superior to those of bangus. “We sell around 4,000 tons of tilapia annually,” Pascual says.

The majority of their tilapia is marketed in General Santos City and Davao City, with some products reaching as far as Bukidnon and Cagayan de Oro. “We have local buyers in the area, as well as distributors,” he adds.

Now back to IPRS. About 10.5 million gallons of water are utilized in the pond, which has the capacity to support 380,000 tilapia fingerlings.

“The tilapia are ready for harvest after approximately five months,” Mosquera says, adding that the fish typically weigh between 350 grams and 500 grams.

The IPRS, as stated earlier, is recognized as an environmentally sustainable approach to tilapia farming. This method has the potential to decrease solid waste accumulation in the pond by concentrating and extracting it from the downstream section of the raceway units.

“In our technology, we have a solid waste collection system installed at the end of the cell,” Mosquera says. “It connects to the sedimentation tanks to allow the water to clear up. The water is then sent to the plant trough or the canal, where aquatic plants are growing. Those plants absorb the residual waste. The clean water is then returned to the pond and recirculated to the cells.”

When inquired about the benefits of IPRS beyond those previously discussed, Mosquera highlights several key points: the system achieves exceptionally high productivity, requires less labor, facilitates year-round fish cultivation, and represents an advanced technology that enhances productivity while minimizing environmental impact.

At the outset of the project, IPRS entails a significant initial investment. However, Mosquera asserts, “If you understand and adhere to the operational principles of the system, the returns will ultimately be favorable.”

He further emphasizes that this technology enables increased production with reduced resources.

Tilapia was very popular during Biblical times as it was a symbol of rebirth in Egyptian art. It was also one of the three main types of fish that can be found in the Sea of Galilee.

The fish is sometimes called “St. Peter’s fish,” due to a story mentioned in the Gospel of Matthew about the apostle Peter catching a fish that carried a coin in its mouth, though the passage didn’t name the fish.

“No fish – with the probable exception of the common carp – is more widely cultured than tilapia,” wrote John E. Bardach, John H. Ryther, and William O. McLarney, authors of Aquaculture: The Farming and Husbandry of Freshwater and Marine Organisms.

The Tilapia Industry Profile, published by the Department of Science and Technology (DOST), said the tilapia produced in the country is mainly for local consumption.

“The produce can be sold fresh, chilled, or live,” the DOST said on its website. “When grown to large size and fileted, tilapia can also be marketed as a premium white fish as its mild tasting lean flesh is flaky for its somewhat firm texture. Some places in the country, smoking of tilapia is done but mainly for the immediate locality.”

Tilapia, while not native to the country, has become the second most widely farmed fish species. Approximately 93% of the total tilapia production is sourced from freshwater, with the remaining 7% derived from brackish and marine environments.

The increasing interest in tilapia farming can be attributed to its promising economic potential, ongoing research aimed at enhancing tilapia species, and the accessibility of commercial farming technologies.

Now, with the advancement of IPRS and the rise in tilapia production, the country may soon have the opportunity to export tilapia.